Manual Gauge Control Air Rings

Reduce Film Thickness Variations by 20-30%

The patented MGC air ring has become an economical best seller in North America, Europe, Asia, Australia and New Zealand. Our customers have reduced film thickness variations by 20-30%.

It is based on Addex’s air ring technology that assures the highest possible output.

Specs

| Size | Diameter | Number of Air Inlets | Number of Control Zones |

|---|---|---|---|

| 3"–6" | 75–150 mm | 36" | 915 mm 6 x 3"/76 mm | 100 |

| 6"–12" | 150–315 mm | 48" | 1220 mm 6 x 4"/102 mm | 132 |

| 13"–20" | 325–500 mm | 56" | 1423 mm 6 x 4"/102 mm | 168 |

| 21"–28" | 525–700 mm | 64" | 1626 mm 8 x 4"/102 mm | 216 |

| 29"–32" | 725–800 mm | 76" | 1931 mm 10 x 4"/102 mm | 272 |

| 33"–36" | 825–900 mm | 76" | 1931 mm 10 x 4"/102 mm | 288 |

| 37"– 40" | 925–1000 mm | 76" | 1931 mm 10 x 4"/102 mm | 304 |

Larger ones are available upon request.

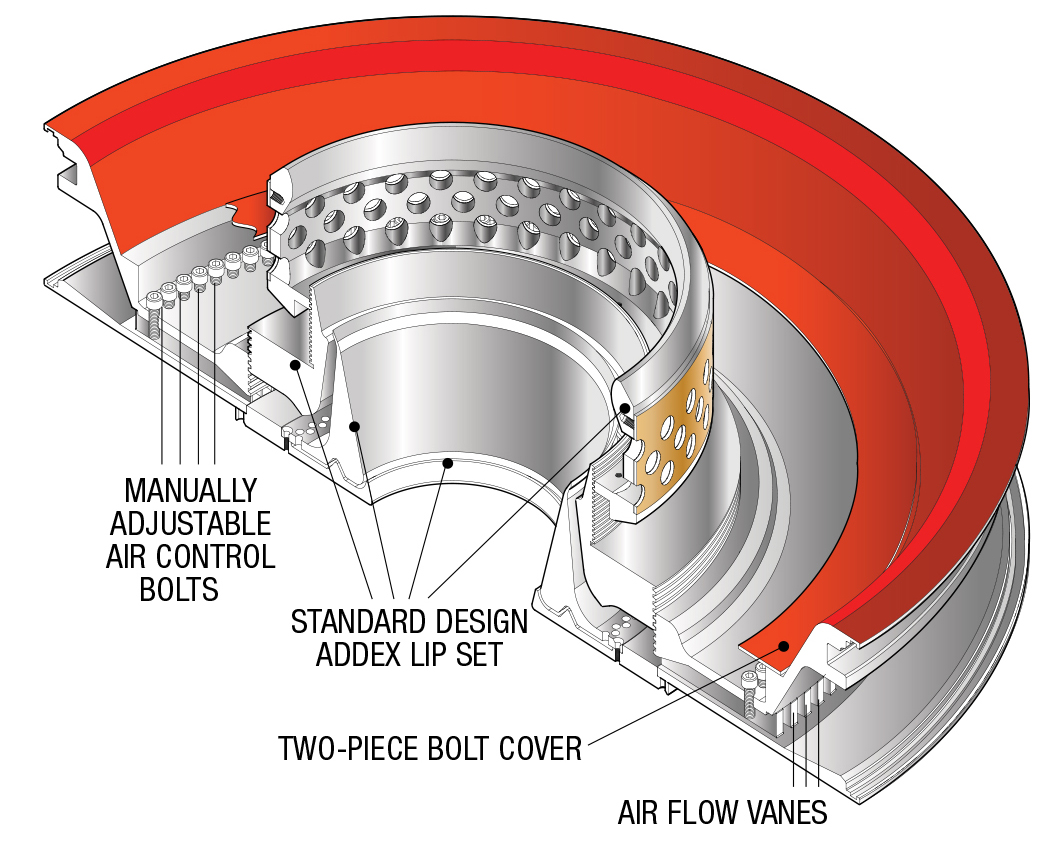

The Addex Manual Gauge Control Air Ring is based upon our Dual Lip Air Ring that has been the standard for the blown film industry worldwide.

The MGC permits selective adjustment to correct film gauge deviation caused by extruder, die, or ambient anomalies by as much as 25% (several customers have achieved a 50% reduction).

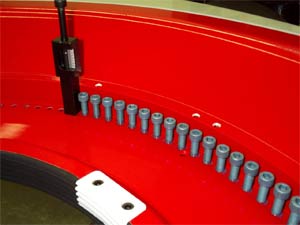

Depending on die size, the MGC is equipped with anywhere from 100 to 304 individually adjustable control bolts in 10mm (3/8”) wide air vanes, providing high resolution, yet requiring only average operator skills.

Because it is manually operated, its price is only a fraction of an automatic system.

Making gauge corrections with the MGC can best be compared to adjusting die bolts to make up for uneven film thickness distribution.

Air Requirements

| US | METRIC | LEGEND: |

|---|---|---|

| D" x 150 = CFM | D mm x 10 = m3/h | D"= Die diameter in inches |

| @ 80ºF & 25"H2O | @ 27ºC & 6.2 KPa | D mm = Die diameter in mm |

| CFM = Cubic feet per minute | ||

| F = Degrees Fahrenheit | ||

| C = Degrees Celsius |

Features

A spot is marked on the film bubble, indicating its orientation, the gauge of the film sample with the marking is measured off line and plotted, and the relative adjusting bolts on the MGC are turned in or out to make corrections. The magnitude of correction per bolt turn can also be determined by before and after film measurements. Although the MGC lends itself to use with stationary as well as oscillating/rotating dies, the latter can control only about half the gauge deviations.

In addition to the MGC, Addex also manufactures a fully automatic External Gauge Control system (EGC), and an automatic Internal Gauge Control system (IGC).

Intensive Cooling Air Rings

All Addex air rings—LFR, MGC and EGC—are now available with Intensive Cooling technology!

Addex has taken air ring technology to a new level by integrating Intensive Cooling technology directly into the dual-flow air ring design. The new Intensive Cooling air rings typically deliver 10%-15% or greater output and better bubble stability—over and beyond Addex’s already high performance, industry-standard dual-flow air ring design.

This newly adapted, patent-pending cooling technology replaces the standard lower lip with a single Intensive Cooling element on Addex’s dual-flow air ring system. The previous low-velocity lower lip is transformed into a high-velocity air stream, creating two primary locking points instead of just one, to significantly improve bubble stability. The Intensive Cooling air rings also include all of the secondary air collar locking points found with the original air ring design. The units are simple and operator friendly, allowing a broad range of processes, blow-up ratios, thicknesses, and materials with minimal adjustments.

The new Intensive Cooling technology applies to all of Addex’s air ring products including automatic profile External Gauge Control (icEGC), Manual Gauge Control (icMGC), and Laminar Flow (icLFR) air rings.